Article Image

Article Image

read

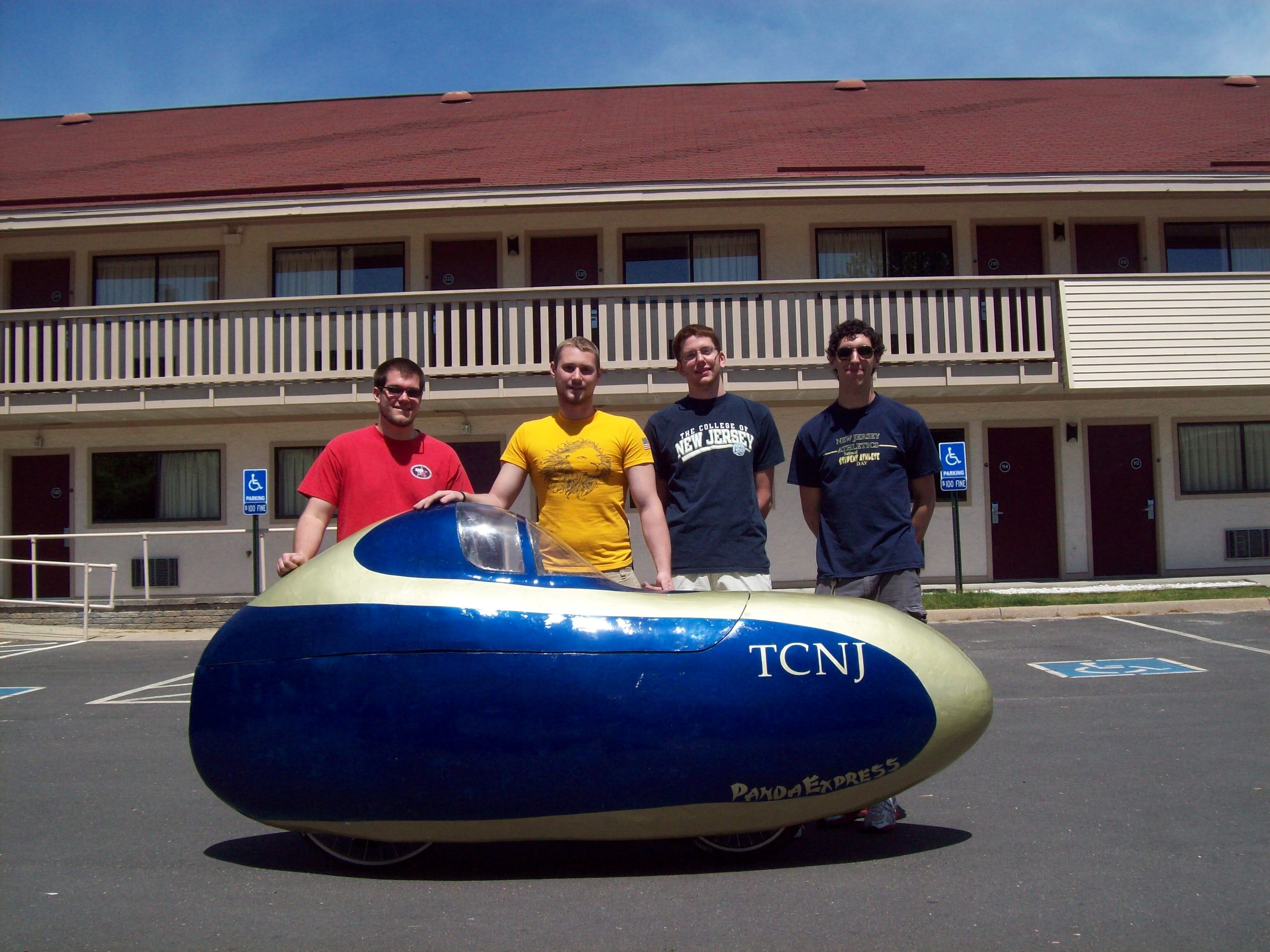

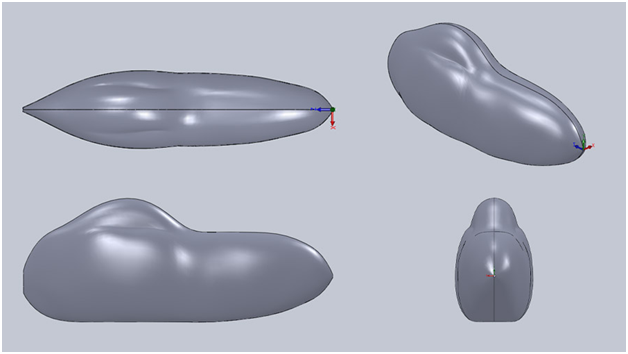

For my senior project I was on a team of 4 competing in the ASME Human Powered Vehicle Challenge. My role was the design and construction of the aerodynamic fairing, while the other three members of the team we’re responsible for the frame, drive train, and project management.

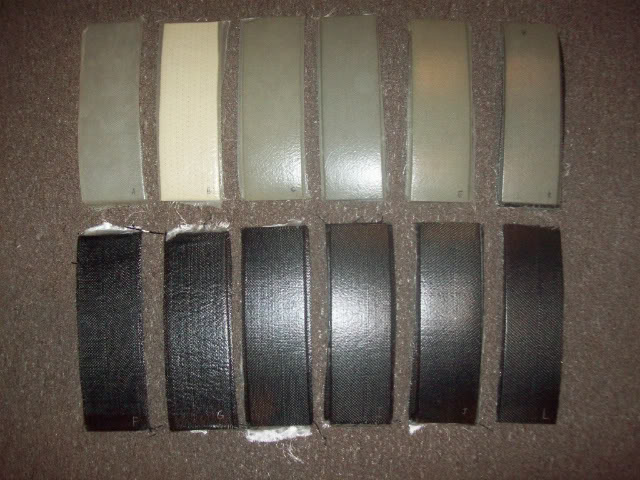

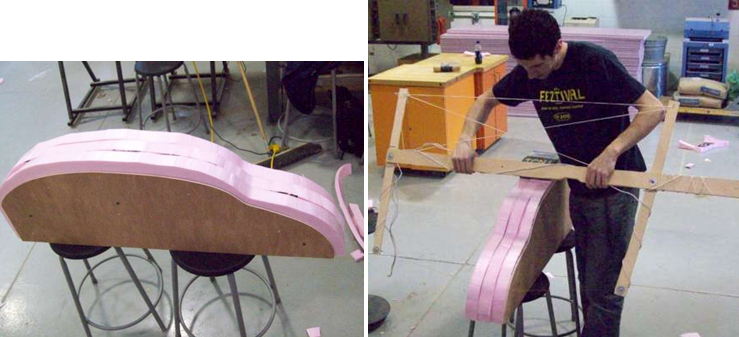

At this time I already had a few years of experience with composite construction from building longboards, which was a valuable base of knowledge to build off of when approaching this project. The photos below document the fairing design, fluid dynamics testing, material testing, and construction of the fairing.

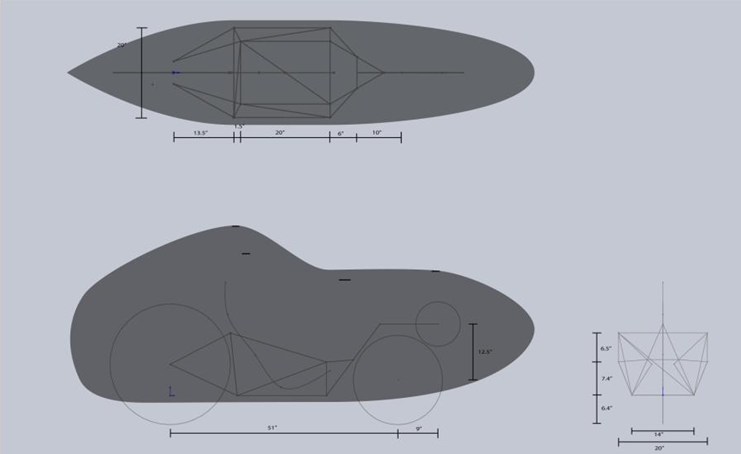

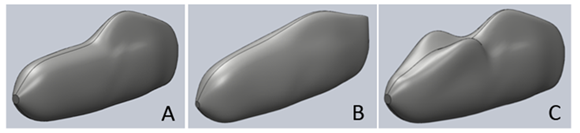

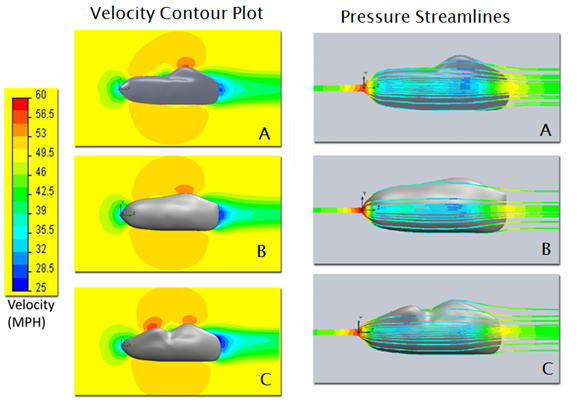

##Design

##Construction

##Completed vehicle